What Is The Best System For Polished Concrete Maintenance?

By Ameripolish®’s Sales & Marketing Manager Greg Cabot (www.ameripolish.com)

This is a question that many of us hear on a regular basis, “What is the best way to maintain polished concrete?” So what is the right method? Is there one method proven to be superior? Today, we are going to explore some field testing reviews, and compare traditional DIP (Diamond Impregnated Pads) to a newer floor maintenance system, which is being referred to as “Composite Resin Abrasives” or CRA. It is best to start this discussion with a definition of both products.

Definition:

Starting with something more familiar to the industry is the Diamond Impregnated Pad. These types of pads, “…are produced by spraying, dipping, or otherwise applying a diamond-filled resin slurry onto the surface of a lofty, nonwoven pad substrate.” – Stone Sole Associates, LLC.

Furthermore, after the phase of being sprayed or dipped, they undergo a thermal curing phase. Product claims for DIPs are centralized around the idea that this method has a “chemical-free” cleaning capability. It is also a common claim that DIPs continuously enhance the aesthetic surface properties of the concrete.

The newer technology of the two systems — dubbed “Composite Resin Abrasives” by its creators, is best described as a, “…hybrid design integrating a non-woven, diamond-free cleaning pad with separate, rigid composite diamond elements.” – Stone Sole Associates, LLC.

What this means — put in more simple terms, is the abrasive portion of this pad is made separately from the non-woven pad, thus the “composite diamond elements” are independent of the pad, and not thermally cured to the pad, like that of DIPs.

Due to the fact that the “Composite diamond elements” are independent of the pad, it allows the diamonds to act primarily on the exposed high points, and pass over the valleys or low points. What this does, over time, is polish down the high points, and transform the surface into a flat “planar condition,” best suited for a clearer, higher quality, light reflection.

Procedure for Testing:

To determine whether the DIPs or Composite Resin Abrasives pad systems were the superior maintenance solution, they were compared head-to-head by Stone Sole Associates LLC. During this testing, daily maintenance protocols simulated the long-term effects of both pad systems.

Two 126-square-foot sections of “highly polished” concrete were sectioned off and “cleaned” using an Auto-Scrubber, utilizing each of the respective maintenance systems. Testing conditions were identical for each cleaning pad: approximately 40 lbs. of machine downforce at 80 ft. per minute forward speed.

It took several days to complete more than 1,000 passes over the floor with each maintenance system. During regular intervals, surface quality measurements were made to check on the effects each system had on the floor with prescribed “daily” use. The quality measurements used were physical surface roughness (Rk), and aesthetic reflective image quality (DOI or Distinctness of Image).

Results:

Sample Evaluation

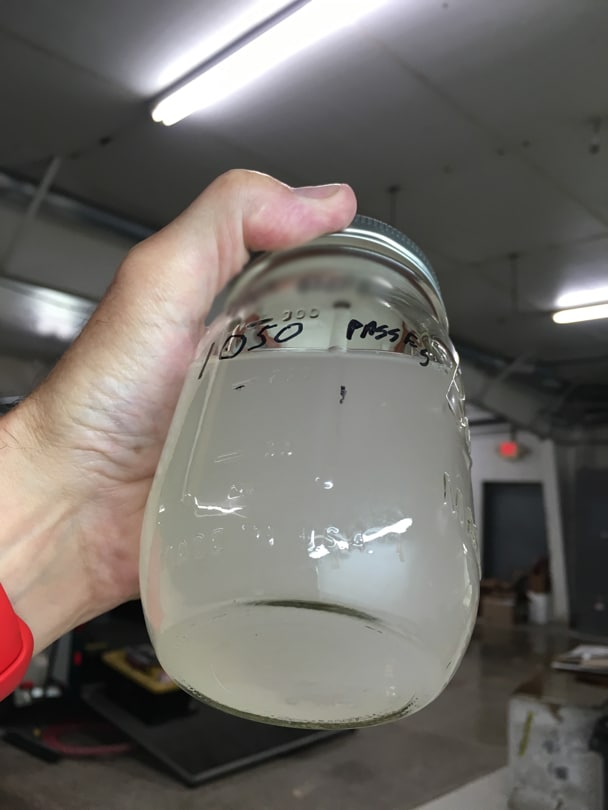

The wastewater being used in the automatic scrubber was collected and evaluated throughout the process. During the 300th pass, the DIP’s reflected a large amount of debris within the water. This indicates that the DIP’s intended to maintain the floor were degrading not only the physical qualities of the floor, but also the aesthetic qualities of the polished concrete surface.

The color of the wastewater was brown in the DIP’s sample, due to the dye that was used on the polished concrete several months before the introduction of the maintenance system; suggesting the maintenance system abraded the concrete surface enough to remove dye.

The Composite Resin Abrasive system produced “virtually no debris” in the wastewater sample collected after the 300th pass, and again later at 1,050 passes. The color of the water in the sample was not obscured with the brown color that the DIP’s sample contained, indicating that the long-term use of Composite Resin Abrasives is much safer for polished concrete than its competitors. Furthermore, the aesthetic qualities of the Composite Resin Abrasive section were significantly better than the DIPs section.

Rk Values:

Now let’s dig into the numbers to reflect a better understanding of what each product is doing to the surface. With regards to Rk values, a lower number indicates a smoother surface, while a higher number indicates a rougher surface. A higher Rk value has more scratches and abrasion on the surface.

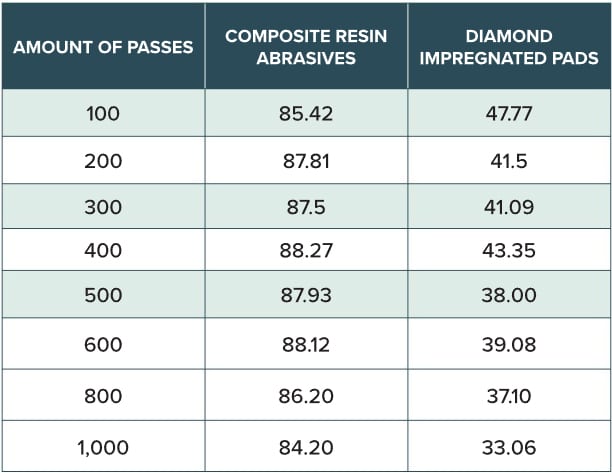

At the start, the DIP’s section of the Polished Concrete surface was measured at a 34.98 Rk condition. The Composite Resin Abrasive’s section was measured at a 36.81 Rk condition, indicating that even at the start of the testing, the Composite Resin Abrasive’s surface was approximately 2 points higher (rougher) than the DIPs section. The following chart shows measurements throughout the test.

As you can see, the DIPs actually increased the Rk values on each of the successive amount of passes, while the Composite Resin Abrasives decreased the Rk values on the same amount of passes. After 1,000 passes, the Composite Resin Abrasive’s section was far lower/smoother (16.62Rk) than the DIP section (85.42Rk). This better explains why in the samples taken of the wastewater of the DIPs, there was color and aggregate inside; with each pass DIPs further scratched and abraded the surface of the polished concrete.

DOI Values:

With regards to DOI values, the higher the number the better. DOI stands for “Distinctness of Image,” which measures reflected image quality/clarity. The scale runs 0-100, the closer to 100 the more “mirror-like” the surface becomes.

The DIPs section of the test area started at a 72.9 DOI reading; and the Composite Resin Abrasive section started at a 67.07. The following chart shows the progress of each system’s DOI readings over 1,000 passes.

As the study shows, even after only 100 passes, the aesthetic quality of the polished concrete surface maintained with DIPs has depreciated by 34.4%. In comparison, Composite Resin Abrasives had increased DOI readings by 27.3% over the course of 100 passes, indicating that it is actually improving the surfaces aesthetic quality over time. The test speaks for itself when it comes to aesthetic qualities within a polished concrete surface: Composite Resin Abrasives are a far superior method to that of DIPs.

Summary:

This study reveals that since the emergence of new technologies, such as Composite Resin Abrasives, there is a maintenance method that provides your polished concrete surfaces with far better results, than that of Diamond Impregnated Pads.

It should be noted that DIPs are actually doing more harm than good when speaking in terms of physical and aesthetic qualities within your polished concrete surface, which essentially defeats the purpose of using it as a daily or weekly cleaning pad.

With the integrity of someone’s job/work at stake, we all want to provide them with a maintenance solution that will keep them proud to return to the job site years later. Choosing Composite Resin Abrasives should be a Concrete Contractors first choice when recommending a long-term maintenance solution.

As many of us know, cost can be a driving factor when it comes to maintenance systems. While some systems have a good price tag value, it is actually more important to pay attention to what your price per square foot is going to be. Often times, when the price tag value seems affordable, the price per square foot will reveal how expensive the product truly is.

It is equally important to know what your maintenance system is doing to your floor. If your polished concrete floor is being ruined by a “cheap” maintenance system, ultimately this will cost you more in the long run!